Understanding Inventory

Introduction to Warehouse Inventory

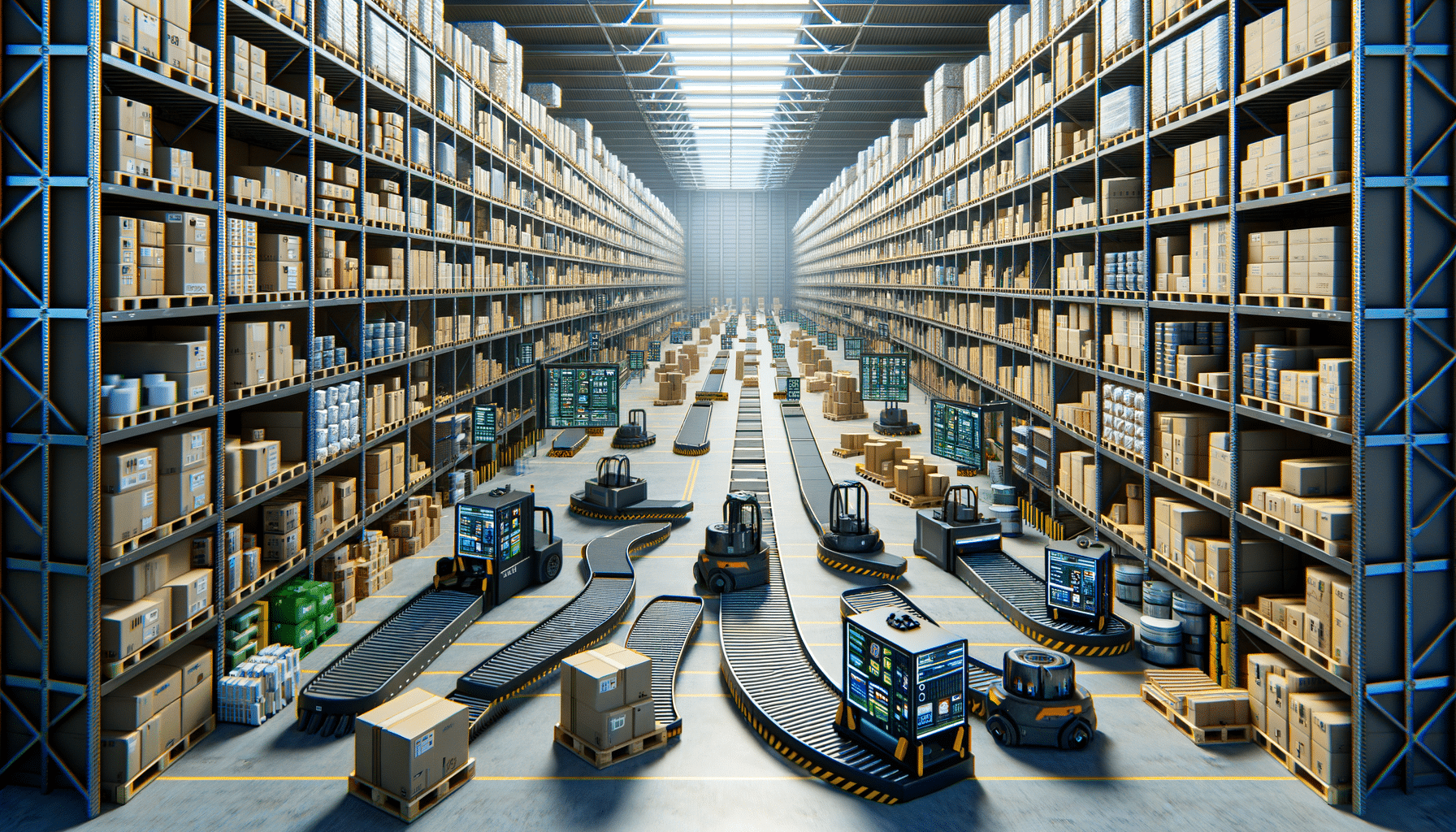

In the realm of logistics and supply chain management, warehouse inventory plays a pivotal role. A well-organized inventory is crucial for a smooth flow of goods and efficient operational processes. Modern inventory management can reduce costs, shorten delivery times, and avoid bottlenecks. Understanding inventory is essential for businesses aiming to optimize their operations and meet customer demands effectively.

Inventory management involves the oversight of non-capitalized assets and stock items. It is a component of supply chain management and ensures that the right quantity of products is available at the right time. Effective inventory management can significantly impact a company’s bottom line, enhancing customer satisfaction and operational efficiency.

Types of Inventory

Warehouse inventory can be categorized into several types, each serving a unique purpose within the supply chain. Understanding these types is essential for effective inventory management.

- Raw Materials: These are the basic materials used in the production of goods. Effective management of raw materials ensures that production processes are not interrupted due to shortages.

- Work-In-Progress (WIP): This refers to partially finished goods that are still in the production process. Managing WIP inventory helps in maintaining a smooth production flow and reducing cycle times.

- Finished Goods: These are the completed products ready for sale to customers. Proper management of finished goods inventory ensures that customer demands are met promptly without overstocking.

- Maintenance, Repair, and Operations (MRO) Goods: These are items used in production processes but not part of the final product. Managing MRO inventory helps in maintaining operational efficiency and reducing downtime.

Each type of inventory requires different management strategies to optimize the supply chain and meet organizational goals.

Inventory Management Techniques

Effective inventory management techniques are crucial for maintaining optimal inventory levels and ensuring operational efficiency. Several methods are commonly used to manage inventory effectively.

- Just-In-Time (JIT): This technique aims to reduce inventory costs by receiving goods only as they are needed in the production process. JIT can significantly reduce holding costs but requires precise demand forecasting.

- ABC Analysis: This method categorizes inventory into three categories (A, B, and C) based on their importance. ‘A’ items are the most valuable, while ‘C’ items are the least. This helps in prioritizing management efforts.

- Economic Order Quantity (EOQ): EOQ is a formula used to determine the optimal order quantity that minimizes total inventory costs, including ordering and holding costs.

- Safety Stock: This is additional inventory held to prevent stockouts caused by demand variability or supply chain disruptions. Safety stock ensures that customer demands are met even in unforeseen circumstances.

Implementing these techniques can help businesses maintain the right inventory levels, reduce costs, and improve customer satisfaction.

Technology in Inventory Management

In recent years, technology has revolutionized inventory management, providing tools and solutions that enhance accuracy and efficiency. Several technological advancements have become integral to modern inventory management.

- Inventory Management Software: These systems automate inventory tracking, providing real-time data and analytics. They help businesses make informed decisions and improve accuracy in inventory management.

- Barcode and RFID Technology: Barcodes and Radio Frequency Identification (RFID) tags facilitate quick and accurate tracking of inventory items, reducing human error and enhancing efficiency.

- Cloud-Based Solutions: Cloud technology allows for remote access to inventory data, enabling businesses to manage inventory from anywhere. This flexibility is particularly beneficial for businesses with multiple locations.

- Artificial Intelligence (AI): AI-driven solutions can predict demand patterns, optimize inventory levels, and automate routine tasks, freeing up human resources for more strategic activities.

Embracing these technological advancements can lead to significant improvements in inventory management, driving efficiency and reducing costs.

Challenges in Inventory Management

Despite the benefits of effective inventory management, businesses often face several challenges that can hinder their efforts. Understanding these challenges is crucial for developing strategies to overcome them.

- Demand Forecasting: Accurately predicting customer demand is challenging, and errors can lead to overstocking or stockouts, both of which are costly.

- Supply Chain Disruptions: External factors such as natural disasters, political instability, or supplier issues can disrupt the supply chain, affecting inventory levels.

- Inventory Visibility: Lack of real-time visibility into inventory levels can lead to inefficient management and decision-making.

- Cost Management: Balancing inventory costs with service levels is a constant challenge, requiring careful planning and execution.

Addressing these challenges requires a combination of strategic planning, technology adoption, and continuous improvement efforts.

Conclusion

Warehouse inventory management is a critical component of supply chain success. By understanding the different types of inventory, employing effective management techniques, leveraging technology, and addressing common challenges, businesses can optimize their inventory processes. This not only enhances operational efficiency but also improves customer satisfaction and profitability. As the business landscape continues to evolve, staying informed and adaptable in inventory management practices will be key to sustaining competitive advantage.