Learn about Air Conditioners Installation

Outline:

– Planning, Sizing, and Choosing a System

– Placement and Site Preparation

– Electrical, Refrigerant Lines, and Ductwork: What to Expect

– Comparing Installation Paths: Window, Portable, Ductless, and Central

– Commissioning, Performance Tuning, and Long‑Term Care (Conclusion)

Introduction:

Air conditioning can transform comfort and productivity, but a solid installation plan is what turns equipment into reliable, efficient cooling. The choices you make—system type, capacity, placement, and commissioning—will echo through your energy bills and day‑to‑day comfort for years. This article walks you through the major decisions with practical context, emphasizing safety, building codes, airflow fundamentals, and the long‑term maintenance that preserves performance.

Planning, Sizing, and Choosing a System

Sizing is the most influential decision in any air conditioner installation. Too small, and the unit runs constantly without catching up; too large, and it short cycles, degrading humidity control and efficiency. A formal load calculation (often referred to as a Manual J in many regions) considers climate zone, square footage, orientation, window performance, insulation levels, infiltration, occupancy, and internal gains. Rules of thumb can mislead; in older, leaky homes, cooling demand can exceed 20 BTU per square foot, while well‑sealed, insulated homes may need 12–18 BTU per square foot. Accurate sizing saves money up front and over the system’s lifetime.

Efficiency ratings help predict operating costs. SEER2 (seasonal efficiency) reflects performance across varied conditions, while EER2 indicates steady‑state efficiency at a specific test point. Heat pumps add HSPF2 to represent heating efficiency. Typical modern split systems range widely: entry‑level units meet regional minimums set by regulators, and high‑efficiency models exceed those thresholds with variable‑speed compressors and smart controls. As a rough guide, a “ton” equals 12,000 BTU/h; over a season, energy use relates to total cooling load divided by seasonal efficiency. Higher efficiency usually means a higher upfront price but lower long‑term cost, especially in hot climates.

System type should match the building and project goals. Window units and portables are quick to install, budget‑friendly, and fine for one room. Ductless mini‑splits offer quiet operation, zoning, and no duct losses—excellent for additions, apartments, or retrofits. Ducted central systems serve entire homes and can integrate filtration, humidity control, and fresh air, but require duct design and more labor. In mixed climates, heat pumps can provide both cooling and heating efficiently, reducing reliance on separate heaters. Consider noise (indoor and outdoor dBA), maintenance access, and future expansion (adding zones or capacity) when choosing a path.

Budget planning should include equipment, labor, permits, accessories, and contingencies. While costs vary by region and complexity, rough equipment and installation ranges often look like this:

– Window or through‑the‑wall: lower initial cost; minimal labor; localized comfort.

– Ductless single‑zone: moderate equipment cost; targeted comfort; simple retrofit.

– Multi‑zone ductless: higher total cost; excellent zoning; streamlined ductless retrofit.

– Ducted central: broader comfort; more labor for ducts; potential for advanced filtration.

Finally, scan the regulatory context. Local codes may specify minimum efficiencies, refrigerant handling requirements, and electrical standards. Newer refrigerants have different safety classifications and environmental profiles; select equipment compliant with local rules and plan installations that prioritize ventilation, clearances, and serviceability.

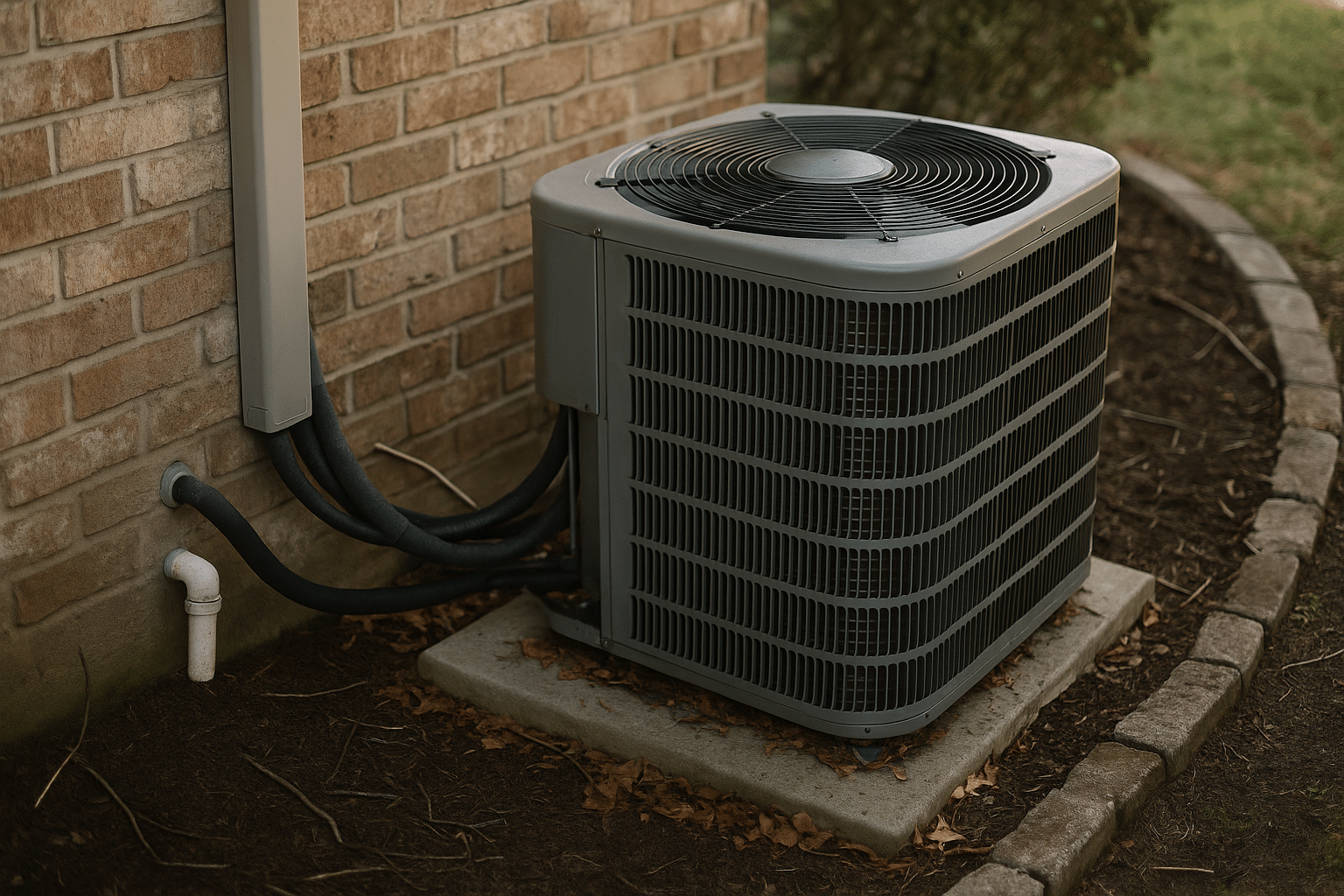

Placement and Site Preparation

Thoughtful placement is the invisible engine of good performance. Indoors, locate air handlers or wall cassettes where air can sweep the occupied zone without being blocked by tall furniture or soffits. Aim to avoid direct sunlight, steamy kitchens, or devices that emit heat, which can skew temperature sensing. In long rooms or open‑plan spaces, angle airflow along the length of the room to prevent stagnant pockets. Provide a clear return‑air path so air can make a full loop; closed doors with no undercut or transfer grille can starve return airflow and raise noise.

For outdoor condensers, airflow and service access are non‑negotiable. Many manufacturers suggest 12–24 inches of clearance on sides and 48–60 inches above for exhaust, but always verify the specific unit’s requirements. Elevate the condenser on a pad or wall brackets to avoid snow, pooling water, and debris. A shaded location can slightly temper heat gain, yet it must remain open to moving air—tight alcoves or under‑deck corners can recirculate hot exhaust and raise head pressure. Where sound matters, consider:

– Locating away from bedroom windows or neighbor patios.

– Using vibration‑damping pads and flexible line supports.

– Orienting the fan discharge away from reflective walls.

Condensate management deserves early attention. Gravity drains should slope continuously, include an accessible cleanout, and be insulated where sweating might occur. Where gravity cannot work, a condensate pump rated for the lift and flow is appropriate; route discharge to an approved location. In humid climates, adding a float switch can shut the system down before a clogged drain causes water damage. Keep drain lines visible or accessible—out of sight often becomes out of mind until ceilings stain.

Penetrations through walls must be sealed and flashed. Use sleeves or escutcheons for line sets, protect insulation with UV‑resistant covers, and apply exterior‑grade sealant to block water and pests. On roofs or exterior walls, follow manufacturer specs for fasteners and corrosion resistance, especially near coasts. Inside, plan routes that minimize sharp bends in line sets or ducts, and reserve straight, short paths for supply runs feeding distant rooms. Good layout shortens installation time and improves airflow, static pressure, and overall comfort.

Before install day, clear a safe work area, verify that structural supports can carry equipment weight, and confirm that dedicated electrical circuits and shutoffs can be placed where code requires. A few hours spent on site readiness can prevent return trips, change orders, and performance compromises that are expensive to correct after the fact.

Electrical, Refrigerant Lines, and Ductwork: What to Expect

Air conditioners demand dedicated, code‑compliant electrical service. The equipment nameplate lists the minimum circuit ampacity (MCA) and maximum overcurrent protection (MOCP); these values guide breaker size and wire gauge. Many split systems run on 240 V with branch circuits sized from roughly 15 A to 60 A depending on capacity and features. Outdoor units typically require a lockable disconnect within sight for servicing. Local codes may require specific grounding methods, surge protection, or ground‑fault protection in certain locations; verify details with the authority having jurisdiction and a licensed electrician.

Panel capacity should be checked during planning. Adding a central system or multiple ductless zones can push a service panel near its limit. A quick load calculation helps determine whether upgrades are prudent. It is also wise to plan a nearby service outlet for maintenance tools, observe clear working space in front of the disconnect, and route conductors in a manner that avoids sharp edges and moisture intrusion. Clear labeling of breakers and shutoffs helps future technicians—and future you.

Refrigerant line sets connect the outdoor unit to the indoor coil or air handler. Diameter depends on capacity and manufacturer specs; liquid lines are often smaller than suction lines, which carry cool, low‑pressure vapor and must be carefully insulated to control condensation and heat gain. Long vertical rises, tight bends, or excessive total length can degrade performance and may require accessories such as traps or oil management solutions. During professional installation, joints are typically brazed under inert gas purge to protect internal surfaces, then evacuated with a high‑vacuum pump (often to 500 microns or lower) to remove moisture and non‑condensables before charging. Handling refrigerant, pressure testing, and charging are regulated tasks reserved for qualified technicians.

If your project involves ducts, the design matters as much as the equipment. Properly sized trunks and branches keep static pressure in a healthy range (many systems target around 0.5 in. w.c., though specifics vary). Undersized returns, restrictive filters, and long, crimped flex runs are common culprits behind noise and weak airflow. Good practice includes:

– Sealing seams with mastic or UL‑rated tape rather than generic cloth tape.

– Insulating supply ducts in unconditioned spaces to at least locally required R‑values.

– Providing generous return paths, especially for closed bedrooms.

– Verifying airflow with a manometer or flow hood during commissioning.

The electrical, refrigerant, and duct paths intersect in one place: safety. De‑energize circuits before work, protect lines from abrasion, and maintain clearances from flues and other heat sources. Good workmanship here is quiet, invisible, and invaluable for performance and longevity.

Comparing Installation Paths: Window, Portable, Ductless, and Central

Different buildings and budgets call for different installation strategies. Window and through‑the‑wall units excel at spot cooling and quick turnarounds. They are straightforward to set and secure, though they may increase background sound and block natural light. Portables offer flexibility where windows or building rules constrain other options, but they can be less efficient due to duct losses and negative pressure that pulls warm air into the room. Both are practical for tenants and short‑term solutions.

Ductless mini‑splits bring high efficiency and quiet operation, with easy zoning across rooms. A single‑zone system targets one space; multi‑zone systems connect several indoor units to one outdoor condenser. Installation typically involves mounting indoor units, drilling a small wall penetration for the line set and control cable, and setting the outdoor unit on a pad or brackets. Because there are no ducts, thermal losses are minimized. Retrofits are efficient and tidy, making ductless a strong option for homes without existing ductwork, condo upgrades where permitted, and additions that would otherwise require invasive construction.

Ducted central systems are well‑suited for whole‑home comfort and advanced filtration. When ducts already exist and are in good shape, a replacement can be cost‑effective and quick. New ductwork adds complexity: room‑by‑room airflow must be balanced, returns added, and leakage sealed. The reward is even comfort across zones, integrated dehumidification options, and a single point for maintenance and control. In mixed or cool climates, a heat‑pump‑based central system can provide year‑round conditioning with efficient shoulder‑season operation.

Consider the tradeoffs in a simple decision matrix:

– Window/Through‑wall: low entry cost, moderate noise, localized comfort, minimal permits.

– Portable: most flexible placement, lowest install effort, lower efficiency, space taken by duct.

– Ductless: high efficiency, zoning, very quiet, premium equipment cost, minimal construction.

– Ducted central: whole‑home coverage, filtration options, higher labor, duct design required.

Timelines vary. A window unit might be secured in an afternoon. A single‑zone ductless often takes a day once electrical is ready. Multi‑zone ductless and ducted central projects can span two to four days, longer with electrical upgrades, permits, or complex routing. Permitting needs differ by locality; electrical work, refrigerant handling, and structural changes commonly require review. Upfront planning helps you pick a path that fits both the building and the calendar.

Commissioning, Performance Tuning, and Long‑Term Care (Conclusion)

Commissioning is where an installation becomes a dependable system. Technicians verify refrigerant integrity with pressure tests, evacuate the lines to remove moisture and non‑condensables, and charge the system according to manufacturer specifications. Airflow is measured and adjusted—many systems target 350–450 CFM per ton—while temperature split across the coil is checked to confirm heat transfer and refrigerant metering. Electrical connections are tightened and labeled, controls programmed, and safety features like float switches tested. Documenting nameplate data, test readings, and serial numbers creates a benchmark for future service.

Once the system is running, small habits sustain performance:

– Replace or clean filters on a schedule (many homes benefit from monthly checks during heavy use).

– Keep 2 feet of clear space around outdoor coils; trim vegetation and rinse fins gently from the inside out.

– Flush or vacuum condensate drains at least annually to prevent clogs and water damage.

– Inspect line‑set insulation and UV covers for wear; repair promptly to stop energy losses.

– Review thermostat programs seasonally; modest setpoint adjustments and setbacks can yield notable savings over time.

Noise, odors, or unexpected cycling patterns are early warning signs. Whistling returns suggest high static pressure; repeated short cycling may point to oversizing or a control setting; musty smells can indicate a drain issue or dirty coil. Address root causes rather than masking symptoms. When heating capability is included, confirm cold‑weather features such as base‑pan heaters or defrost logic are active and that drain paths remain clear in freezing conditions.

For owners and property managers, a maintenance plan—whether in‑house or with a service provider—protects warranties and keeps utility costs predictable. A simple log of filter dates, coil cleanings, and service visits helps spot trends before they become repairs. If major changes occur (new windows, added insulation, remodels), revisit load assumptions and control settings; the “right size” today can drift after an upgrade. Equally important, ensure all work involving refrigerants and high‑voltage wiring is performed by qualified professionals to comply with regulations and maintain safety.

In closing, careful planning, accurate sizing, sensible placement, and thorough commissioning are the pillars of a successful installation. Choose an installation path that matches your building and timeline, budget for quality labor, and commit to routine care. Do that, and your system will reward you with steady comfort, controlled humidity, and measured energy use—season after season.